Scale is a essential equipment which used to measure weight of sample in laboratories and it play a critical role in each tests experiments. They can be divided in to two types as mechanical and electronics. The accuracy of scale depends upon the the type of scales and if it is electronics scale depend on selected range. i.e if you try to measure 0.5g using 0-10 kg range scale it would be gives considerable error to your readings.

T ripple beam balance

Planed Preventive Maintenance (PPM) check list

The objective of Planed preventive maintenance is a continuous, precise operation of your equipment, to secure your investments for the long term and to guarantee correct and proper function.These are common things have to be considered on PPM but some mandatory things may include in manufacturer's service manual and they are depend on the product specifications and can't predefine for each and every production.

The maintenance of balances covers cleaning and some test procedures. Internal adjustments should not be done. If the test results differ much from the balance's specifications, it is advisable to ship the balance to the manufacturer.

The tests should be done on-site in the laboratory. Moving the balance to a workshop is anyway not a good idea. Any moving can cause additional problems.

Needed tools

Beside the calibration weights for balances without internal calibration weights, no special tools are needed. A proper set of screwdrivers, the technical manual for the balance and a clean and bright workplace is all we need.

Step 1: Inspection

Before starting any maintenance or repair, start with a short visually inspection:

Is there any contamination or anything else unusual?

Is there any contamination or anything else unusual?

Does the doors close/open smoothly?

Does the doors close/open smoothly?

Do the switches work properly?

Do the switches work properly?

Is the zero-point display stable (without a load)?

Is the zero-point display stable (without a load)?

Make a note of all objections. We come later to these points. First we have to clean the balance.

Step 2: Cleaning

Use a fine paintbrush to remove sample residues. Often the weighing pan can be removed for easier cleaning.

Use a fine paintbrush to remove sample residues. Often the weighing pan can be removed for easier cleaning.

If there is stain, use a damp cloth and a mild soap solution. Do not make the cloth too wet. Make sure that no moisture enters the balance.

If there is stain, use a damp cloth and a mild soap solution. Do not make the cloth too wet. Make sure that no moisture enters the balance.

Wipe the balance with a soft and dry cloth.

Wipe the balance with a soft and dry cloth.

The glass of the weighing chamber of an analytical balance can be cleaned with a common window cleaner.

The glass of the weighing chamber of an analytical balance can be cleaned with a common window cleaner.

Step 3: Maintenance

If the sliding doors move sluggishly, take out the doors and clean the rails and the edges of the glass doors. Do not lubricate. Oil or grease absorb more dirt over time and the function gets worse.

This also applies for the interior of the balance: Do not lubricate anything. Just clean all components from dust and dirt. Any additional substance interfere with the balance's mechanic.

Important! Never lubricate a balance unless the manufacturer has expressly indicated it.

Step 4: Standard tests

Beside the calibration procedure some tests can be done, in order to verify the accuracy of the balance. The result of these tests will show the deviation from a perfect balance with no deviation at all. Since such a balance in practice do not exists, there can be deviations expected. The problem now is to decide, if these differences are within the tolerance of the manufacturer. Therefore we have to know the specifications of the balance, compare the results and make a decision: Yes, the test results are within the tolerance, the balance is OK; or no, out-off the tolerance, the balance has to be repaired.

Since the technician is not the operator of the balance and does not necessarily know for what kind of measurements the balance is used, it is recommended to do the tests, record the test results and deviations and let the operator decide, if the results can be accepted and the balance is precise enough for future measurements.

The following performance tests can be done:

Reproducibility (Repeatability)

Reproducibility (Repeatability)

Cornerload

Cornerload

Linearity

Linearity

The procedures to perform these test are explained below. Also a test chart for each test can be downloaded. The test charts can be printed out and the test results can be filled in. Later they can handed over to the responsible person.

The tests can be performed semi-annual as part of the preventive maintenance of all the other laboratory equipment.

Are there are significant changes, check again if there are any influences from outside which could create the problem (static, air draft, warm-up, vibration, etc.) and repeat the test. If the balance still fails the check, the balance has to be send to the manufacturer for a recalibration.

Reproducibility (Repeatability)

Reproducibility means that a repeated weighing of the same object must deliver the same weight reading. A calibration weight is measured for ten times and the readings are put into the test chart. After each weighing cycle the balance has to be returned to zero.

The following Reproducibility Test Chart can be printed out and used as a test report:

Reproducibility Test Chart

40 KB Download

40 KB Download

Cornerload

A cornerload test is performed in order to find out if the balance delivers the same weight reading for a given object regardless of its position on the weighing pan.

Position a calibration weight at various locations on the weighing pan. The reading should be the same, within a few digits, at all positions.

Note! A balance which already delivered large deviations during the reproducibility test will also deliver wrong results also here.

The following Cornerload Test Chart can be printed out and used as a test report:

Cornerload Test Chart

21 KB Download

21 KB Download

Linearity

Linearity testing verifies the accuracy of the balance at intermediate values of weight. Since a laboratory balance will often be used to weigh items much smaller than the maximum capacity of the balance, this is an important test.

The following Linearity Test Chart can be printed out and used as a test report:

Linearity Test Chart

29 KB Download

29 KB Download

T ripple beam balance

|

| Digital Scale |

Care must be taken when measuring using scale on followings,

- Scale must be trace to Zero (Adjust to zero) before place the sample.

- It must be balance well horizontally and should be firmly stable on the place which it has placed.

- Never place any weight on the scale which more than maximum measurable value, It will damage strange inside the balance.

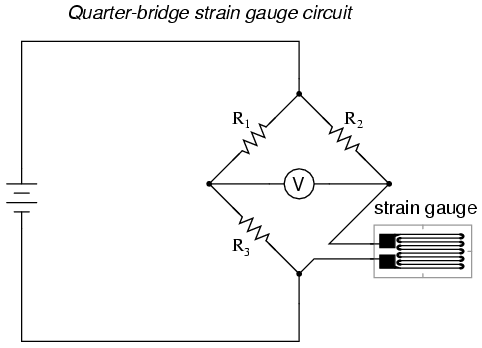

Strain Guage

Strain gauge is a device which change resistance with respect to the stress on the device. The resistance changes can be measure very precisely using Winston Bridge circuit as follows.

The objective of Planed preventive maintenance is a continuous, precise operation of your equipment, to secure your investments for the long term and to guarantee correct and proper function.These are common things have to be considered on PPM but some mandatory things may include in manufacturer's service manual and they are depend on the product specifications and can't predefine for each and every production.

The maintenance of balances covers cleaning and some test procedures. Internal adjustments should not be done. If the test results differ much from the balance's specifications, it is advisable to ship the balance to the manufacturer.

The tests should be done on-site in the laboratory. Moving the balance to a workshop is anyway not a good idea. Any moving can cause additional problems.

Needed tools

Beside the calibration weights for balances without internal calibration weights, no special tools are needed. A proper set of screwdrivers, the technical manual for the balance and a clean and bright workplace is all we need.

Step 1: Inspection

Before starting any maintenance or repair, start with a short visually inspection:

Is there any contamination or anything else unusual?

Is there any contamination or anything else unusual? Does the doors close/open smoothly?

Does the doors close/open smoothly? Do the switches work properly?

Do the switches work properly?  Is the zero-point display stable (without a load)?

Is the zero-point display stable (without a load)?Make a note of all objections. We come later to these points. First we have to clean the balance.

Step 2: Cleaning

Use a fine paintbrush to remove sample residues. Often the weighing pan can be removed for easier cleaning.

Use a fine paintbrush to remove sample residues. Often the weighing pan can be removed for easier cleaning. If there is stain, use a damp cloth and a mild soap solution. Do not make the cloth too wet. Make sure that no moisture enters the balance.

If there is stain, use a damp cloth and a mild soap solution. Do not make the cloth too wet. Make sure that no moisture enters the balance.  Wipe the balance with a soft and dry cloth.

Wipe the balance with a soft and dry cloth.  The glass of the weighing chamber of an analytical balance can be cleaned with a common window cleaner.

The glass of the weighing chamber of an analytical balance can be cleaned with a common window cleaner.Step 3: Maintenance

If the sliding doors move sluggishly, take out the doors and clean the rails and the edges of the glass doors. Do not lubricate. Oil or grease absorb more dirt over time and the function gets worse.

This also applies for the interior of the balance: Do not lubricate anything. Just clean all components from dust and dirt. Any additional substance interfere with the balance's mechanic.

Important! Never lubricate a balance unless the manufacturer has expressly indicated it.

Step 4: Standard tests

Beside the calibration procedure some tests can be done, in order to verify the accuracy of the balance. The result of these tests will show the deviation from a perfect balance with no deviation at all. Since such a balance in practice do not exists, there can be deviations expected. The problem now is to decide, if these differences are within the tolerance of the manufacturer. Therefore we have to know the specifications of the balance, compare the results and make a decision: Yes, the test results are within the tolerance, the balance is OK; or no, out-off the tolerance, the balance has to be repaired.

Since the technician is not the operator of the balance and does not necessarily know for what kind of measurements the balance is used, it is recommended to do the tests, record the test results and deviations and let the operator decide, if the results can be accepted and the balance is precise enough for future measurements.

The following performance tests can be done:

Reproducibility (Repeatability)

Reproducibility (Repeatability) Cornerload

Cornerload Linearity

LinearityThe procedures to perform these test are explained below. Also a test chart for each test can be downloaded. The test charts can be printed out and the test results can be filled in. Later they can handed over to the responsible person.

The tests can be performed semi-annual as part of the preventive maintenance of all the other laboratory equipment.

Are there are significant changes, check again if there are any influences from outside which could create the problem (static, air draft, warm-up, vibration, etc.) and repeat the test. If the balance still fails the check, the balance has to be send to the manufacturer for a recalibration.

Reproducibility (Repeatability)

Reproducibility means that a repeated weighing of the same object must deliver the same weight reading. A calibration weight is measured for ten times and the readings are put into the test chart. After each weighing cycle the balance has to be returned to zero.

The following Reproducibility Test Chart can be printed out and used as a test report:

Reproducibility Test Chart

40 KB Download

40 KB DownloadCornerload

A cornerload test is performed in order to find out if the balance delivers the same weight reading for a given object regardless of its position on the weighing pan.

Position a calibration weight at various locations on the weighing pan. The reading should be the same, within a few digits, at all positions.

Note! A balance which already delivered large deviations during the reproducibility test will also deliver wrong results also here.

The following Cornerload Test Chart can be printed out and used as a test report:

Cornerload Test Chart

21 KB Download

21 KB DownloadLinearity

Linearity testing verifies the accuracy of the balance at intermediate values of weight. Since a laboratory balance will often be used to weigh items much smaller than the maximum capacity of the balance, this is an important test.

The following Linearity Test Chart can be printed out and used as a test report:

Linearity Test Chart

29 KB Download

29 KB Download

Analytical Weighing Balance

ReplyDeleteAnalytical Weighing Balance - Buy electronic analytical weighing balance online at the best price in Singapore. We offer the best analytical weighing balance scales online for Industrial business.

to get more - http://www.lianseng-scales.com.sg/product-category/laboratory-scales/analytical-precision-balance//

Your info is really amazing with impressive content. Excellent blog with an informative concept.

ReplyDeleteWeighing Balance

Great Post,we are leading online supplier of Laboratory Balances for your needs. Find all the industry-standard Analytical Lab Balances at best prices.

ReplyDeleteHello Dear..

ReplyDeleteI appreciate your Informative post and It's very helpful.thanks for sharing Keep it up!

Weighing Balance | Testing Instruments | Bursting Strength Tester Digital

This is Really an Amazing Article. Your Article is Really Good. Please Share Something on Analytical Balances as Your Article has Always Good Content with Informative Information.

ReplyDeleteUrethral Swab

Nasopharyngeal Swab

Science Lab Equipment

Science Laboratory Supplies

Shop for analytical and laboratory weighing scales in Singapore. Trust our products for precise measurements in your scientific experiments. Visit our website now! Analytical balance.

ReplyDelete